Table of Contents

ToggleCan You Anodize Stainless Steel

Introduction

Can You Anodize Stainless Steel? Unraveling the Possibilities

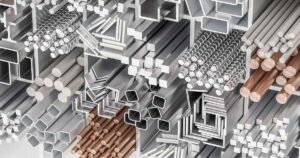

Anodizing is a popular process used to enhance the surface properties of metals, particularly aluminum. However, when it comes to stainless steel, a material known for its corrosion resistance and durability, the question arises: can you anodize stainless steel? This guide delves into the feasibility, methods, and implications of anodizing stainless steel.

Understanding Anodizing

The Basic Principles of the Anodizing Process

Anodizing is an electrochemical process that increases the thickness of the natural oxide layer on the surface of metal parts. It’s most commonly associated with aluminum, where it adds corrosion resistance, surface hardness, and the ability to hold dyes for coloring.

Stainless Steel and Anodizing

Assessing the Suitability of Stainless Steel for Anodizing

Stainless steel, unlike aluminum, has a different oxide layer composition, making the traditional anodizing process used for aluminum ineffective. The chromium-rich oxide layer on stainless steel already provides substantial corrosion resistance and a protective barrier.

Alternative Techniques

Exploring Other Surface Treatments for Stainless Steel

Since conventional anodizing is not suitable for stainless steel, alternative methods like electro-polishing or passivation are often used. These processes enhance the natural protective layer of stainless steel without the need for anodizing.

The Challenges of Anodizing Stainless Steel

Understanding the Limitations and Technical Aspects

Anodizing stainless steel is not straightforward due to its inherent properties. The challenges include achieving uniform thickness, color consistency, and ensuring the integrity of the protective layer. Specialized techniques and careful control of the process parameters are necessary.

Benefits of Surface Treatment on Stainless Steel

Why Consider Enhancing Stainless Steel’s Surface?

While stainless steel is already durable and corrosion-resistant, additional surface treatments can further increase its resistance to wear, improve its aesthetic appeal, and provide a more uniform finish.

The Process Explained

A Step-by-Step Overview of Anodizing Stainless Steel

- Cleaning: Thoroughly cleaning the stainless steel to remove any contaminants.

- Pre-Treatment: Applying specific chemical treatments to prepare the surface.

- Anodizing: Using specialized techniques to form a protective layer.

- Sealing: Ensuring the longevity of the treatment.

Comparing Stainless Steel to Aluminum

Differences in Anodizing Processes and Results

The anodizing process for stainless steel differs significantly from that of aluminum, both in technique and outcome. The resulting finish on stainless steel is more subtle and less varied in color compared to aluminum.

Practical Applications

Where Anodized Stainless Steel is Used

Anodized stainless steel is used in applications where additional surface properties are desired, such as in certain architectural, automotive, and culinary contexts. The enhanced surface can provide added value in terms of both function and aesthetics.

Maintenance and Care

How to Preserve the Quality of Anodized Stainless Steel

The maintenance of anodized stainless steel is crucial for preserving its appearance and protective properties. Regular cleaning with mild detergents and avoiding abrasive materials are recommended to maintain the integrity of the anodized layer.

Innovations in Metal Treatment

Future Trends in Anodizing and Stainless Steel

Advancements in metal surface treatments continue to evolve, potentially opening up new possibilities for anodizing stainless steel or developing similar processes that could achieve comparable results.

Frequently Asked Questions

Addressing Common Inquiries About Anodizing Stainless Steel

- Can stainless steel be colored through anodizing? Traditional anodizing used for coloring is not effective on stainless steel, but other techniques can be used to achieve colored finishes.

- How does anodized stainless steel compare to untreated stainless steel? Anodized stainless steel generally offers enhanced surface characteristics, such as increased wear resistance and a uniform appearance, compared to untreated stainless steel.

Conclusion

Summing Up the Prospects of Anodizing Stainless Steel

In summary, while traditional anodizing is not suitable for stainless steel, alternative surface treatment methods can provide

similar benefits. The feasibility of anodizing stainless steel depends on various factors, including the specific alloy and the desired outcome. Understanding the nature of stainless steel and the limitations of current technology is key to exploring surface treatment options.

Final Thoughts

Embracing the Potential of Stainless Steel Surface Treatments

While anodizing stainless steel in the traditional sense may not be feasible, the exploration of alternative methods reflects the ongoing innovation in metal surface treatments. By understanding the properties of stainless steel and the available techniques, one can effectively utilize this versatile metal in various applications, enhancing its natural strengths and aesthetic appeal.

This comprehensive guide has explored the topic of anodizing stainless steel, shedding light on the process, its feasibility, and alternatives. Whether for industrial, architectural, or decorative purposes, understanding the potential and limitations of surface treatments on stainless steel is crucial for achieving the desired results and extending the material’s lifespan.