How to Solder Stainless Steel: Your Complete Guide

Soldering stainless steel can seem like a daunting task due to the material’s unique properties. However, with the right knowledge and tools, you can achieve strong, durable bonds for your projects. This guide will walk you through the process of soldering stainless steel, from preparation to finishing touches.

Understanding Stainless Steel Soldering

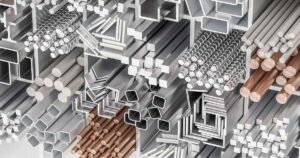

Before diving into the soldering process, it’s important to understand what makes stainless steel different. Stainless steel is known for its corrosion resistance, which comes from a thin layer of chromium oxide on its surface. This layer can make soldering challenging, as it prevents the solder from properly adhering to the metal.

Materials and Tools Needed

- Stainless steel pieces to solder

- Solder (specifically designed for stainless steel)

- Flux (appropriate for stainless steel)

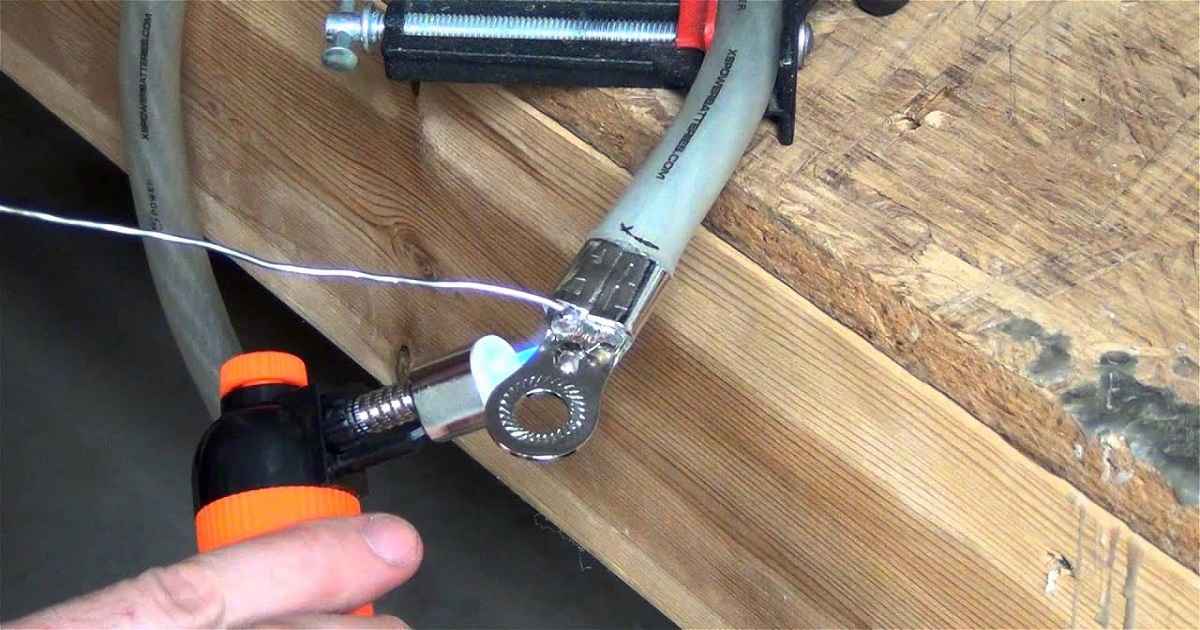

- Soldering iron or torch

- Wire brush or sandpaper

- Cleaning solvent

- Protective gear (gloves, goggles)

Preparation: The Key to Success

- Clean the Stainless Steel: Begin by thoroughly cleaning the surfaces to be soldered. Use a wire brush, sandpaper, or a specialized cleaning solvent to remove any dirt, grease, or oxidation from the metal. This step is crucial for ensuring the solder adheres properly.

- Apply Flux: Once the stainless steel is clean, apply a layer of flux to the areas that will be joined. Flux helps prevent further oxidation during the soldering process and improves the flow of solder.

Soldering Process

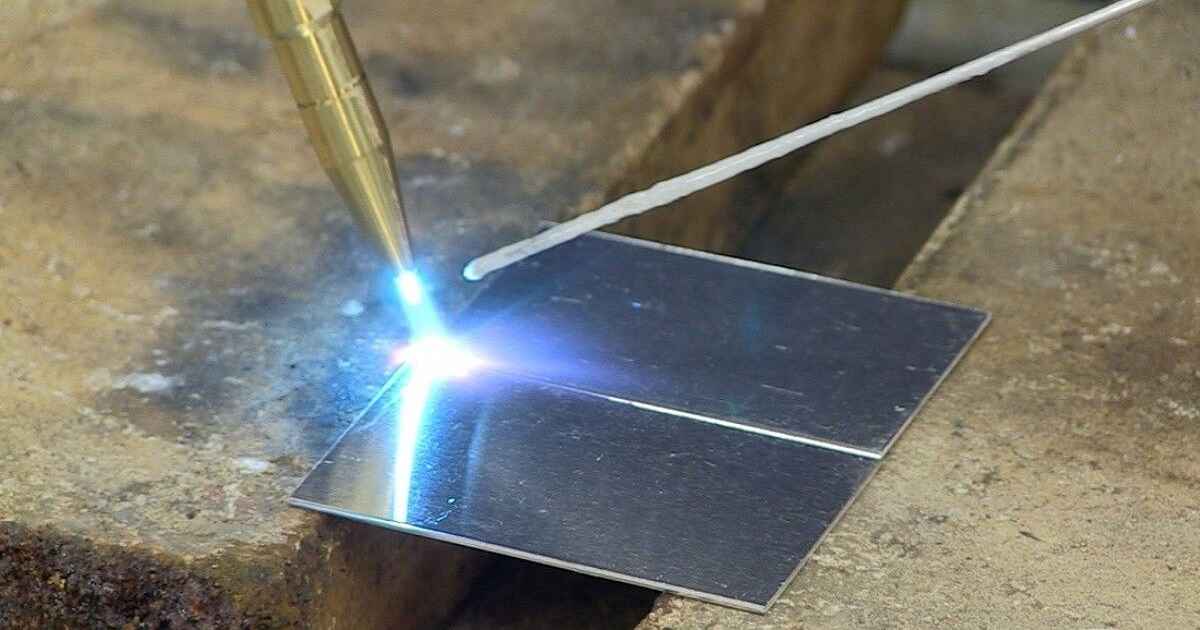

- Heat the Metal: Using your soldering iron or torch, gently heat the stainless steel pieces to be joined. It’s important to heat the metal evenly to avoid warping or damaging the material.

- Apply the Solder: Touch the solder to the joint once the metal is hot enough. The heat should melt the solder, allowing it to flow into and fill the joint. Remember, the heat source should heat the metal, not the solder directly, for best results.

- Cool Down: After the solder has been applied, remove the heat and allow the joint to cool naturally. Avoid moving the pieces until the solder has solidified to ensure a strong bond.

Finishing Touches

After the solder has cooled and solidified, it’s time for some finishing touches. Clean any flux residue from the joint with a solvent to prevent corrosion. You may also want to polish the soldered area to match the surrounding metal’s finish.

Troubleshooting Common Issues

Soldering stainless steel can present challenges, such as poor adhesion or weak joints. If you encounter these issues, revisit your preparation steps. Ensuring that the stainless steel is clean and properly fluxed is often the key to resolving soldering problems.

Safety Considerations

Always wear appropriate protective gear, such as gloves and goggles, when soldering. Work in a well-ventilated area to avoid inhaling fumes from the flux and solder.

FAQs

- Can I use any solder for stainless steel?

- No, it’s important to use a solder specifically designed for stainless steel to ensure a strong bond and corrosion resistance.

- Why is flux necessary for soldering stainless steel?

- Flux prevents oxidation during the soldering process, allowing the solder to adhere properly to the stainless steel.

- How can I avoid warping the stainless steel while soldering?

- Heat the metal evenly and avoid applying too much heat to one area to prevent warping.

By adhering to these guidelines and techniques, you’re well on your way to becoming proficient in soldering stainless steel, enhancing the quality and durability of your metalworking projects.

Conclusion

Soldering stainless steel requires patience and attention to detail. By following these steps and tips, you can achieve strong, durable bonds for your projects. Remember, practice makes perfect. Don’t be discouraged by initial challenges; with time and experience, your soldering skills will improve.

Soldering stainless steel is not just about joining two pieces of metal; it’s about creating lasting connections that resist corrosion and withstand the test of time. Whether you’re working on jewelry, household repairs, or custom fabrications, mastering the art of soldering stainless steel opens up a world of possibilities for your projects.