How to Mig Weld Stainless Steel

How to MIG Weld Stainless Steel: A Comprehensive Guide

Welding is an essential skill in various industries, including construction, automotive, and manufacturing. Among the various welding methods, Metal Inert Gas (MIG) welding is popular for its versatility and efficiency, especially when working with stainless steel. This guide will walk you through the process of MIG welding stainless steel, covering everything from selecting the right equipment to the finishing touches.

Understanding the Basics of MIG Welding Stainless Steel

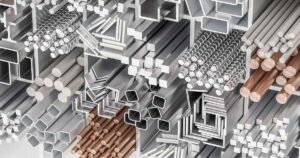

Before diving into the specifics, it’s crucial to understand what makes stainless steel different from other metals and why MIG welding is a suitable method for working with it. Stainless steel is known for its corrosion resistance, a characteristic provided by the chromium content. When welding stainless steel, the goal is to maintain this corrosion resistance while achieving a strong, durable weld.

Equipment and Materials Needed

- MIG welder: Ensure it’s capable of handling stainless steel.

- Welding wire: Use a wire specifically designed for stainless steel, such as 308L for general use or 316L for marine applications.

- Shielding gas: A mixture of argon and carbon dioxide (CO2) is commonly used, though argon with a small percentage of oxygen can also be effective.

- Safety gear: Including a welding helmet, gloves, and protective clothing.

Preparation for Welding

- Clean the Metal: Stainless steel must be free of any contaminants, such as oil, dirt, or rust, which can affect the quality of the weld. Use a stainless steel brush and appropriate cleaning solvents.

- Cut and Fit: Prepare your metal pieces, ensuring they fit together well without large gaps.

- Set Up Your Welder: Adjust the settings on your MIG welder according to the thickness of the stainless steel and the type of weld required.

Welding Process

- Tack Welds: Start by making small tack welds to hold the pieces together. This prevents warping and maintains alignment.

- Welding Technique: Use a steady, controlled motion, moving the welder in a straight line or a slight weaving pattern, depending on the weld’s requirements. The key is to maintain a consistent speed and distance from the metal.

- Shielding Gas Flow: Ensure the flow rate of the shielding gas is sufficient to protect the weld pool from contamination but not so high that it causes turbulence.

Post-Welding Steps

- Cooling: Allow the welded piece to cool naturally. Avoid using water or other rapid cooling methods, as this can lead to warping or cracking.

- Cleaning: Remove any slag or spatter using a stainless steel brush. For a cleaner finish, a passivation process can be applied to restore the corrosion resistance of the welded area.

- Inspection: Check the weld for any defects, such as cracks or porosity. Non-destructive testing methods can be used for critical applications.

Tips for Successful MIG Welding of Stainless Steel

- Use the Right Wire: The choice of welding wire significantly affects the weld’s quality and the stainless steel’s corrosion resistance.

- Control Heat Input: Stainless steel is sensitive to heat, so it’s important to manage the heat input to prevent warping and distortion.

- Practice: As with any skill, practice is key to mastering MIG welding of stainless steel. Experiment with different settings and techniques to find what works best for your specific project.

Safety Precautions

Welding, by nature, involves risks. Proper safety measures are essential to prevent accidents. Always wear the appropriate safety gear, work in a well-ventilated area, and be aware of the hazards associated with welding fumes and UV radiation.

Conclusion

MIG welding stainless steel requires a combination of the right equipment, preparation, and technique. By following the steps outlined in this guide, you can achieve strong, durable welds while maintaining the material’s corrosion resistance. Whether you’re working on a small home project or a large industrial application, the ability to weld stainless steel effectively is a valuable skill in your welding repertoire.