Can You Braze Stainless Steel? Understanding the Process and Techniques

The question of whether you can braze stainless steel is common among both hobbyists and professionals in the metalworking field. Brazing is a method of joining metals by melting a filler metal into the joint. This comprehensive guide will delve into the feasibility, techniques, and best practices for brazing stainless steel.

Introduction to Brazing Stainless Steel

What is Brazing?

Brazing is a metal-joining process wherein a filler metal is heated above its melting point and distributed between two or more close-fitting parts by capillary action. The filler metal solidifies upon cooling, forming a strong joint.

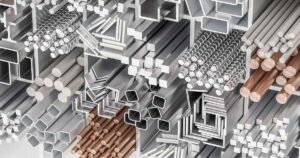

Characteristics of Stainless Steel

Stainless steel is known for its corrosion resistance, strength, and aesthetic appeal. It’s an alloy that primarily consists of iron, chromium, and nickel. These elements give stainless steel its unique properties, which also influence how it reacts to brazing.

Can You Effectively Braze Stainless Steel?

Feasibility of Brazing Stainless Steel

Yes, you can braze stainless steel. However, it requires specific techniques and considerations due to its unique properties, such as its thermal conductivity and oxide layer.

Preparing Stainless Steel for Brazing

Cleaning and Surface Preparation

Thorough cleaning and proper surface preparation are critical for successful brazing. Stainless steel surfaces must be free of oils, dirt, and oxides to ensure good adhesion of the filler metal.

Choosing the Right Brazing Filler Metal

Selecting an appropriate filler metal is crucial. For stainless steel, filler metals like silver alloys, copper-phosphorus alloys, and nickel alloys are commonly used, depending on the application and required strength of the joint.

Brazing Techniques for Stainless Steel

Using the Right Flux

Flux is essential in brazing stainless steel to remove and prevent oxides from forming during the heating process. The choice of flux depends on the filler metal and the brazing conditions.

Heat Control During Brazing

Proper heat management is crucial. Stainless steel has a high thermal expansion rate, which can lead to distortion if unevenly heated. The brazing process should be controlled to ensure uniform heat distribution.

Safety Measures in Brazing

Personal Protective Equipment

Brazing involves high temperatures and potentially hazardous materials. Wearing appropriate personal protective equipment, such as gloves, eye protection, and fire-resistant clothing, is essential.

Ventilation and Fume Extraction

Proper ventilation is important to avoid inhalation of harmful fumes. A well-ventilated workspace or a fume extraction system is recommended when brazing stainless steel.

Common Challenges and Solutions

Avoiding Thermal Distortion

Due to stainless steel’s thermal properties, managing heat to prevent warping or distortion of the metal is a challenge. Techniques to mitigate this issue would be discussed.

Ensuring Strong Joints

Achieving a strong, leak-proof joint is essential, especially in applications involving pressure or stress. We’ll provide tips for ensuring joint integrity through proper technique and filler metal selection.

Aftercare and Inspection

Cleaning After Brazing

Post-brazing cleaning is important to remove flux residues and any oxidation. Methods for effective cleaning would be outlined.

Inspecting the Brazed Joints

Quality inspection of the brazed joints is crucial for safety and functionality. Techniques for inspecting and testing the strength of brazed joints in stainless steel would be discussed.

Conclusion: Mastering the Art of Brazing Stainless Steel

In conclusion, brazing stainless steel is indeed possible and can be highly effective with the right knowledge and techniques. This guide aims to equip readers with the understanding and skills needed to successfully braze stainless steel, whether for repairs, fabrication, or artistic purposes.

This guide aims to provide a thorough understanding of the brazing process specifically for stainless steel, addressing common concerns, providing practical tips, and ensuring safety measures are well understood.