Can You Blue Stainless Steel? Exploring the Possibilities and Techniques

When it comes to modifying the appearance of metals, bluing is a well-known technique primarily used for steel. This leads to a common question: Can you blue stainless steel? In this comprehensive guide, we’ll explore the feasibility, methods, and considerations involved in bluing stainless steel.

Understanding the Basics of Bluing

What is Bluing?

Bluing is a process of treating steel to create a thin protective layer of magnetite, Fe3O4, which gives the steel a blue-black appearance. It’s commonly used for decorative purposes and to provide a degree of corrosion resistance.

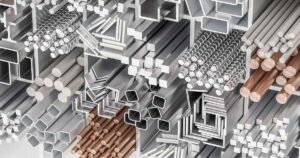

The Composition of Stainless Steel

Stainless steel, an alloy primarily composed of iron, chromium, and often nickel, is renowned for its corrosion resistance and strength. The presence of chromium creates a natural passive layer of chromium oxide, which protects it from rust and tarnish.

Can Stainless Steel Be Blued?

Challenges with Bluing Stainless Steel

The inherent corrosion resistance of stainless steel makes it resistant to traditional bluing methods. These methods, which work well on carbon steel, are less effective on stainless steel due to its chromium content and the protective oxide layer.

Alternative Methods for Stainless Steel

While traditional hot bluing is less effective, other techniques like chemical bluing, and physical vapor deposition (PVD) can be used to achieve a similar appearance on stainless steel.

Methods of Bluing Stainless Steel

Chemical Bluing Techniques

Chemical solutions specifically designed for stainless steel can be used to achieve a blued appearance. These chemicals react with the surface to produce a blue-black finish, although the results may vary depending on the steel’s composition and surface preparation.

Physical Vapor Deposition (PVD)

PVD is a more modern technique where a thin film of another material is deposited on the stainless steel’s surface. This method can produce a range of colors, including blue, and is known for its durability.

Preparing Stainless Steel for Bluing

Cleaning and Surface Preparation

Proper surface preparation is crucial for bluing stainless steel. The surface must be meticulously cleaned and free of oils, dirt, and oxidation to ensure an even and successful application.

Safety Considerations

Working with chemicals or in a PVD process requires strict adherence to safety protocols, including using protective gear and working in a well-ventilated area.

The Bluing Process: Step-by-Step Guide

Applying Chemical Solutions

This section would provide a detailed guide on how to apply chemical bluing solutions, including tips on application methods, temperature control, and timing for optimal results.

PVD Process Overview

Here, we would explain the PVD process in a simplified manner, outlining how it’s conducted, the kind of equipment required, and the characteristics of the finish it produces.

Aftercare and Maintenance

Protecting the Blued Finish

Once blued, stainless steel requires proper care to maintain its appearance. This involves regular cleaning and avoiding harsh chemicals that might damage the finish.

Touch-ups and Repairs

Over time, the blued finish may wear or scratch, requiring touch-ups. This section would offer advice on how to perform minor repairs and maintain the aesthetic appeal of the blued stainless steel.

Exploring the Aesthetics and Applications of Blued Stainless Steel

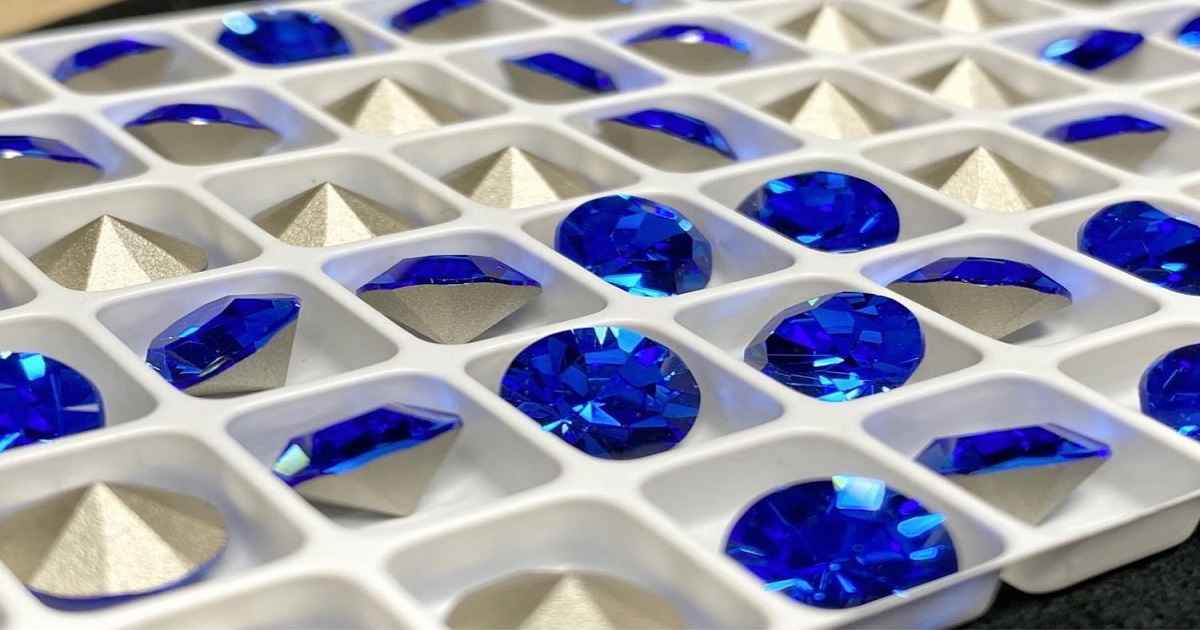

Visual Appeal of Blued Stainless Steel

The unique blue-black sheen achieved through the bluing process adds an aesthetic value to stainless steel items. This finish is particularly sought after in custom metalwork, artistic pieces, and even in some industrial applications where appearance is a key factor.

Common Uses of Blued Stainless Steel

Traditionally, bluing has been associated with firearms. However, blued stainless steel can also be found in decorative items, jewelry, watch parts, and even in architectural elements where a distinctive look is desired.

DIY vs. Professional Bluing Services

When to Choose DIY Bluing

For hobbyists or those looking to experiment on small projects, DIY bluing can be a rewarding endeavor. This section would discuss the feasibility and considerations for undertaking bluing projects at home, including the availability of consumer-grade bluing kits.

Seeking Professional Services

For larger, more complex, or high-stakes projects, professional bluing services are recommended. These services have the expertise and equipment to achieve a high-quality finish, especially important for items where durability and precision are critical.

The Pros and Cons of Bluing Stainless Steel

Advantages of Bluing

This part of the guide would outline the benefits of bluing stainless steel, such as enhanced aesthetic appeal, added corrosion resistance, and the ability to customize the look of stainless steel items.

Limitations and Considerations

Despite its advantages, bluing stainless steel also has limitations. The process might not be suitable for all stainless steel grades, and the finish can be susceptible to wear and scratches over time. Maintenance and care requirements would also be discussed here.

Tips for Successful Bluing of Stainless Steel

Choosing the Right Materials and Tools

A successful bluing project starts with the right materials and tools. This section would provide advice on selecting the appropriate stainless steel grade, bluing solutions, and equipment for either DIY or professional-level projects.

Troubleshooting Common Issues

We would address common problems that might arise during the bluing process, such as uneven coloring, patchiness, or inadequate adhesion, and provide practical solutions and tips for avoiding these issues.

Environmental and Health Considerations

Handling Chemicals Responsibly

Bluing involves the use of chemicals that can be harmful if not handled correctly. This section would emphasize the importance of responsible chemical handling, including proper storage, disposal, and adherence to environmental regulations.

Ensuring Personal Safety

Safety is paramount when working with chemicals and high-temperature processes. We would offer guidance on personal safety measures, including the use of protective gear and working in a controlled environment.

Final Thoughts: Embracing the Art of Metal Finishing

The Artistic Aspect of Metal Bluing

Bluing stainless steel is not just a technical process; it’s also an art form. This final section would reflect on the creative possibilities that bluing offers, encouraging readers to appreciate the skill and craftsmanship involved.

Expanding Your Metalworking Skills

For those interested in metalworking, learning how to blue stainless steel can be a valuable skill. We would encourage readers to further explore this and other metal finishing techniques to broaden their crafting and DIY abilities.