Can you Weld Stainless to Mild Steel

Can You Weld Stainless to Mild Steel? The Ultimate Welding Guide

So, you’re wondering, can you weld stainless to mild steel? The short answer is yes, but there’s a bit more to it than just a straightforward “yes”. Welding these two metals together is not uncommon and can be quite effective when done correctly. Let’s break it down and see how it’s done.

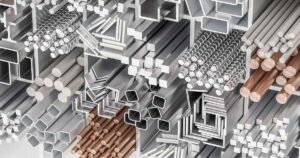

1. Understanding the Basics: What Are Stainless Steel and Mild Steel? First things first, let’s talk about our materials. Stainless steel is known for its corrosion resistance, thanks to a high chromium content. Mild steel, on the other hand, is a carbon steel with a relatively low carbon content, making it more malleable and less brittle.

2. The Challenges of Welding Stainless Steel to Mild Steel The main challenge in welding these two metals lies in their different compositions and properties. Stainless steel and mild steel expand and contract at different rates when heated. This can lead to warping, cracking, or even a weak joint if not handled correctly.

3. Choosing the Right Welding Method There are a few different welding methods that can be used to join stainless steel to mild steel. The most common ones are MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and stick welding. Each method has its pros and cons, so the choice depends on the specifics of your project.

4. Preparing for the Weld Proper preparation is key. Clean the surfaces thoroughly to remove any grease, oil, or dirt. It’s also a good idea to grind down the edges to create a clean, even surface for welding.

5. Selecting the Right Welding Rod The choice of welding rod is crucial. A rod with a composition that’s compatible with both stainless steel and mild steel is essential. Typically, a 309L rod is recommended, as it’s designed for welding dissimilar metals.

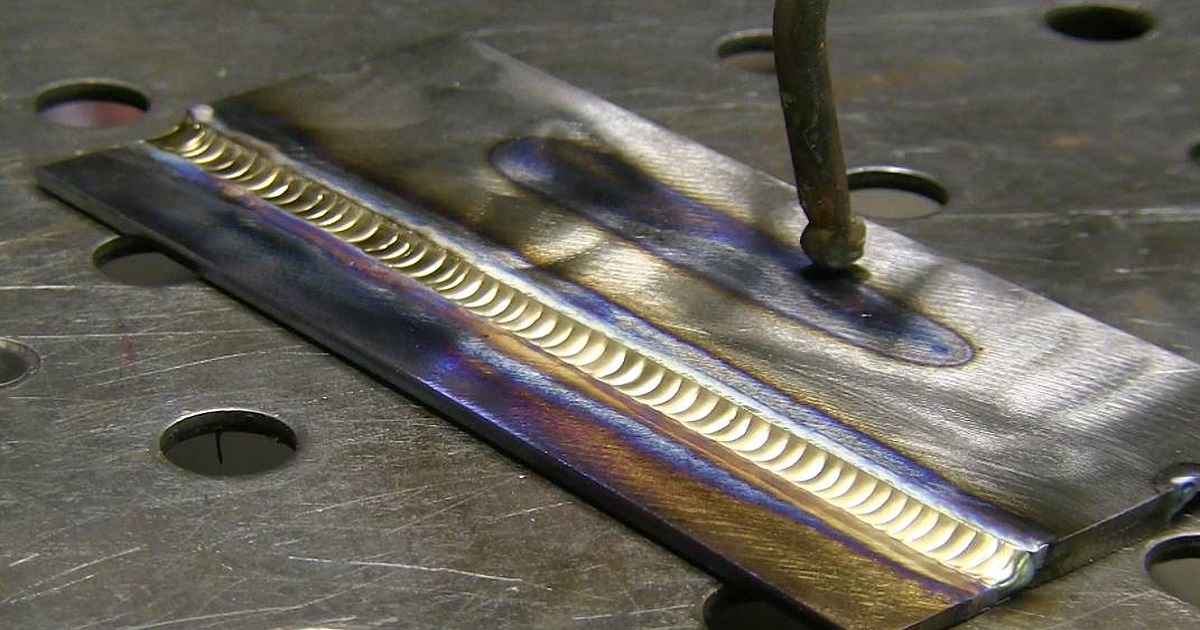

6. The Welding Process: Tips and Techniques When you start welding, control is vital. Use a lower heat setting to prevent warping and maintain a steady, consistent speed. It’s also important to monitor the heat input and distribution to ensure a strong bond.

7. Post-Welding Considerations After welding, it’s not uncommon to see some discoloration on the stainless steel side. This can usually be cleaned up with a suitable polishing method. Also, check the weld for any signs of cracking or weak spots.

8. Common Mistakes to Avoid One of the biggest mistakes is using the wrong type of filler material. Another common error is not controlling the heat properly, which can lead to a weak joint or damage to the metals.

9. Safety First: Protective Gear and Precautions Safety cannot be overstressed. Always wear the appropriate protective gear, including a welding helmet, gloves, and protective clothing. Ensure proper ventilation in your workspace to avoid inhaling harmful fumes.

10. The Benefits of Welding Stainless to Mild Steel Welding stainless to mild steel can be beneficial in various applications where you need the strength of steel and the corrosion resistance of stainless. This combination can be particularly useful in automotive applications, construction, and mixed-material sculptures.

11. Advanced Techniques and Tips For those looking to refine their technique, exploring advanced welding methods and practicing on scrap pieces can be beneficial. Experimenting with different welding speeds, angles, and heat settings can help you find the sweet spot for your specific project.

Conclusion: Mastering the Art of Welding Stainless to Mild Steel Welding stainless steel to mild steel is indeed possible and can be quite successful with the right knowledge, tools, and techniques. Whether you’re a seasoned welder or a curious beginner, understanding the nuances of welding these two metals is a valuable skill in your toolbox.